dxf store 2d or 3d drawing

DXF File Information

What is a DXF File?

DXF files (files with a .dxf file extension) are a type of CNC File called vector CAD files. Vector CAD Files contain objects such as:

- Lines

- Polygons

- Circles

- Arcs

- Bezier Curves

- Text

DXF stands for Drawing eXchange Format. The Drawing Exchange Format was created past Autodesk for their AutoCAD CAD software. It was originally introduced with AutoCAD 1.0 in Dec 1982, so it'due south been around for a long time.

Most CAD and CAM software will open, create and edit DXF files. Importing a DXF file into a CAD program and then exporting information technology is the best way to convert DXF files to a different CAD cartoon file format. Many drawing programs such every bit Adobe Illustrator and CorelDraw will too open, edit, and save DXF files, so this is another possibility. For artistic work, a drawing plan may be easier. For creating mechanical components, CAD software is better.

Nosotros offer this drove of Free DXF Files to get you lot started.

Why would I need Costless DXF Files?

As mentioned, DXF Files human activity equally CNC Patterns that guide your machine on where to cut. There's a lot of fun to be had with decorative and artistic CNC projects. Such projects don't require a lot of precision and are only 2 to 2 i/2D, and so they're like shooting fish in a barrel to make with a CNC Router, Laser, Waterjet, or Vinyl Cutter. Sometimes we're calculation a design equally a decorative element on top of a precision machined part, similar this engraving on a bandsaw mitre gage:

Many times, the hardest part of these kinds of projects is coming up with artwork. It's line art, which is relatively straightforward to convert to CAD and thence to CAM and finally thousand-code. Only getting decent line art to start can exist a pain. Especially for non-artists.

With this page, I'g making decent quality line fine art available for free to CNC'ers so y'all can have dandy CNC Patterns for your projects.

Equally you tin see, nosotros divide the files into Categories like Animal, Holiday, and Vehicles. I accept a LARGE library of gratis dxf files that you'll be able to download above. I don't have nearly all of them up withal, but I will exist steadily adding to the page until I have them all available.

Below, you'll also find information well-nigh how to become the most out of the gratis dxf files, so exist certain to check out the commodity below on optimizing your CAM for DXF Cutting Files.

I accept big plans for the folio, so stay tuned. If y'all haven't already subscribed to our email newsletter, become hooked up correct below so yous don't miss out equally new developments unfold.

Optimizing Your CAM for DXF Cutting Files

To ensure y'all accept an first-class experience with our free DXF files we would similar to share with you some information that volition make information technology easier for y'all to be successful with our DXF files.

The first thing you will want to practise once y'all download a Gratuitous DXF file is to unzip the file with a file extraction program. Once yous unzip the file binder you will see ii files available. One of your unzipped files will stop with .dxf and the other will end with .jpg (.dxf files are for cutting .jpg files are for viewing purposes only).

You will primarily be focused on either importing or opening the DXF file into your CAM or CAD based software program. If you are trying to edit the design piece of work you can use a program like Corel Describe or Adobe Illustrator to make quick changes to the existing DXF file.

I know a lot of individuals that are new to the CNC industry like to try Inkscape but I have non had very proficient success with importing and opening my DXF files into that item plan. I believe it is due to how Inkscape was developed based off older versions of the DXF file format.

If you lot are importing the DXF file or opening information technology into your CAM software you will want to exist sure to disable your offset tooling part. If you are unable to disable the start office birthday then you lot will want to reduce your get-go value every bit small equally information technology will go (.001″). This function may likewise exist referred to equally "Tool Compensation."

The reason to do this is you want the cut to go right downward the centerline of the vectors in these files. Anything else can atomic number 82 to poor results or errors that foreclose your CAM packet from generating 1000-cdoe.

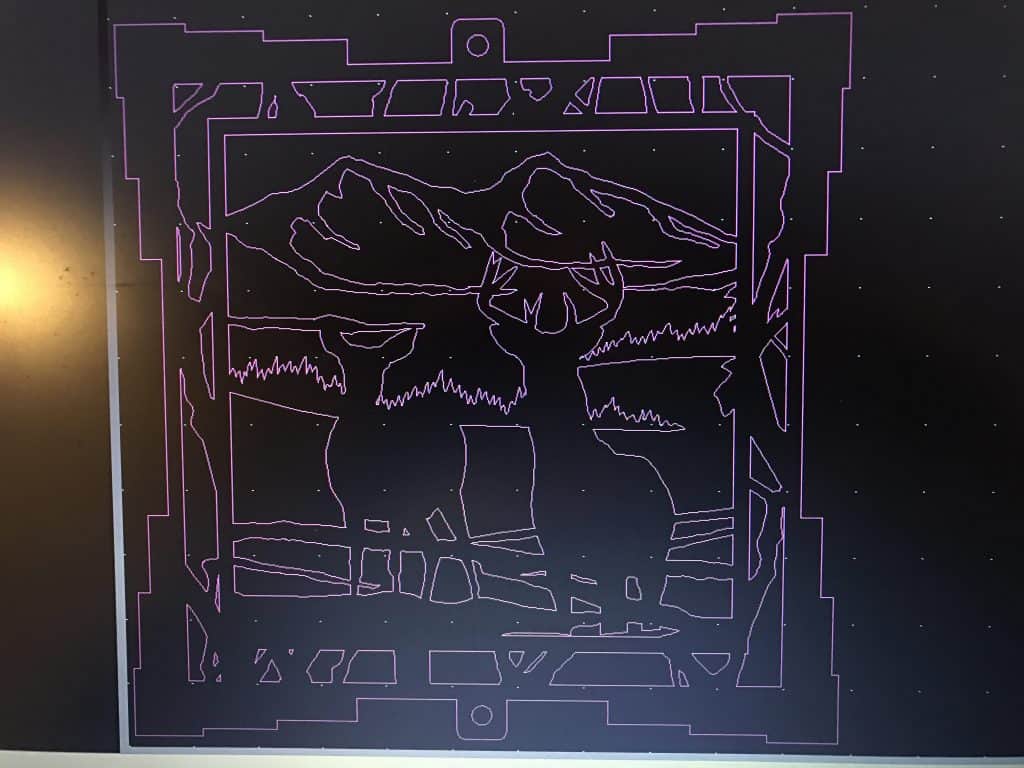

Here is an case of what a DXF file looks like when information technology is imported without any offsets:

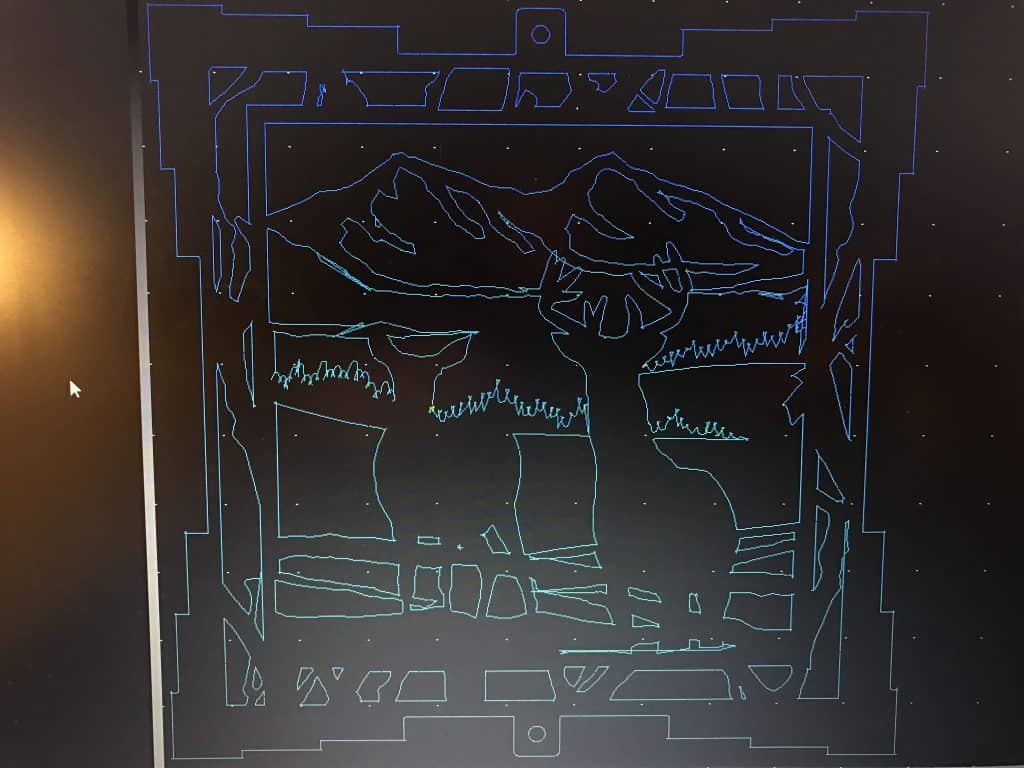

This is what a DXF file looks like with a medium offset:

Find at that place is not much visible departure, however this medium get-go has created over 100 unwanted intersections in the geometry.

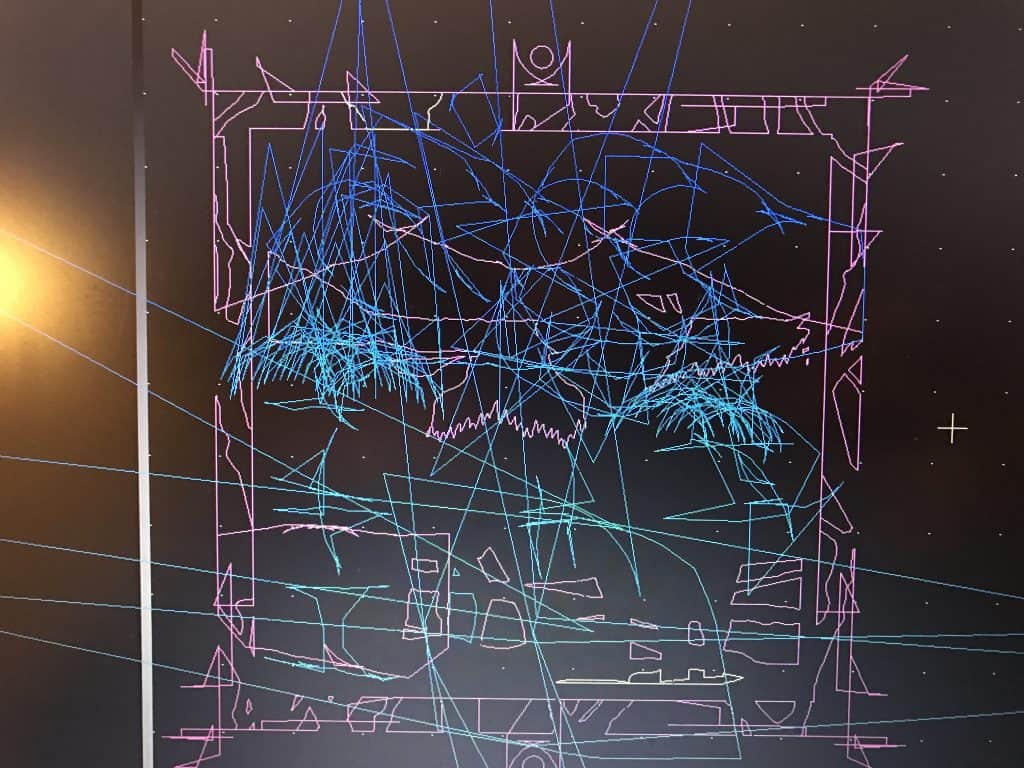

This is what a DXF file looks similar with a large offset:

The divergence is dramatic and alarming. Don't be fooled by seeing something like this, clearly the issue is due to improper tool path offsetting.

If your CAM system is detecting overlapping lines or giving you error codes the primary reason for this is that your auto commencement feature is toggled on and your CAM system is literally redrawing the design work to conform an unnecessary offset. If you import the DXF file and you are seeing thousands of footling lines very close to each other yous import options may be configured incorrectly for lines and arcs when they should be set for polylines.

Once you are able to import the DXF file into your CAM software you volition discover that most of our CNC DXF files come up with two images of the same design.

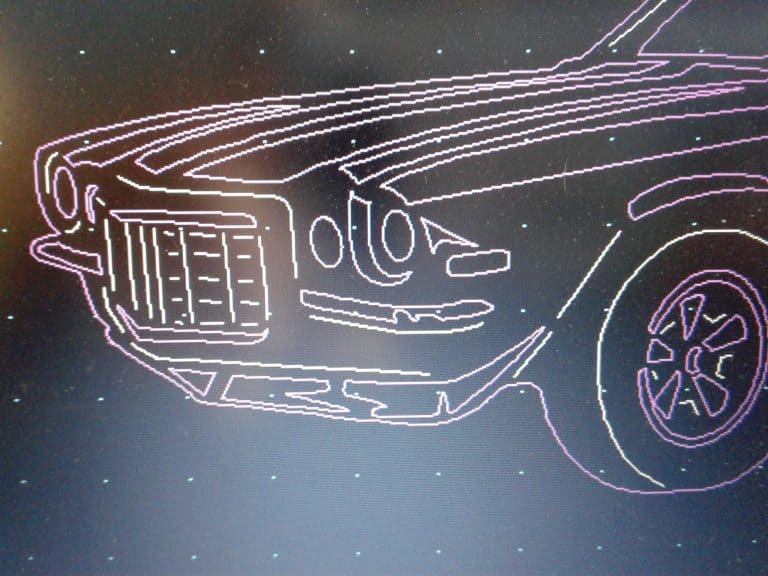

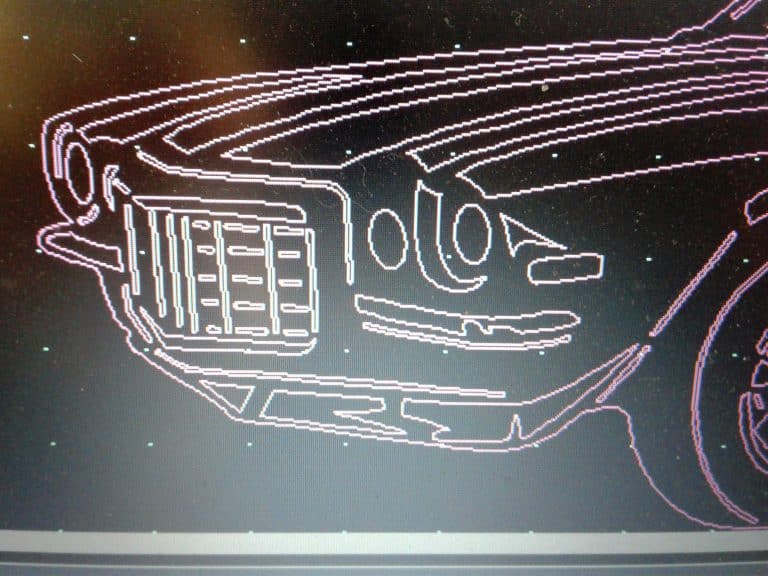

For example, here's a Camaro DXF File:

If you zoom in on the DXF file yous have imported you lot will run across 1 design includes single lines like you meet in this example (single lines are referred to as open cutting paths).

If you zoom in on the other paradigm included in the DXF file you lot imported you will see that it does not contain whatsoever single lines. (In this design all the cut paths are referred to as closed cut paths):

Now that you are familiar with some of the basics of importing your DXF file you lot will want to either delete the closed path or open up cut path version of the design. As a rule of thumb all Plasma and Router based CNC cut systems will employ the open cutting path version of the design (if you are using a plasma or router based CNC cut system you tin delete the closed path version of the DXF file design) Call up to save the file under a separate proper noun so that you do not lose access to both versions of the design.

Now if you are operating a laser or waterjet based CNC cutting system you will want to apply the closed cut path version of the blueprint. ( If you are using a laser or waterjet based cutting system you tin delete the open cut path version of the DXF file design) Remember to save the file under a separate proper name and so that yous do not lose access to both versions of the blueprint.

If yous program to cut the our DXF files with a CNC plasma cutting system it is recommended that y'all use a plasma cutting system capable of cutting at or below 40 amps. Fine tip consumables between 20 and 40 amps will yield excellent to very good results. Amperage is directly tied to the size of your plasma stream cut width.

For the very best results brand certain to do several straight line exam cuts to minimize the cutting width in the material that you lot will exist cut. Stand up off altitude, cut speed and air pressure all have an bear on on the cut width and quality of your cut. Every plasma cutting system is different and the only truthful way to get truly astonishing results is through trial and mistake. With a fiddling time and practice you will minimize your cut width and improve your cut quality that will effect in achieving great particular and minimal make clean upwardly.

Source: https://www.cnccookbook.com/free-dxf-files/

0 Response to "dxf store 2d or 3d drawing"

Post a Comment